Soil and Groundwater Remediation

SOIL AND GROUNDWATER REMEDIATION

- Explore a variety of remedial techniques to choose the best option for your project and needs based on a combination of timeliness, effectiveness, and cost.

- Strive to remediate impacted media in a timely and cost-efficient manner.

- Experienced Operations & Maintenance technicians oversee all remediation system operations

Excavation and Off-SiteDisposal Program

Remediation

Systems

Excavation and Off-Site Disposal

Creek Run has prepared many excavation and off-site disposal plans and implemented this type of remediation throughout Indiana and Ohio. Excavation and off-site disposal of contaminated soil is the most rapid approach for removing contaminant mass, preventing transfer of contaminants to liquid and gaseous phases with subsequent migration into off-site areas, and achieving soil cleanup goals. Excavation/disposal of impacted soil and adsorbed petroleum molecules is a highly effective method of contaminant removal. Excavation/disposal is particularly effective for relatively shallow, low permeability, clay-rich soils that are difficult to remediate by in-situ methods.

Short term costs associated with this technology are relatively high, depending on the volume of soil to be excavated. However, if complete removal of impacted soil is achieved, long term remediation and monitoring costs are significantly reduced. Excavation is a disruptive remedy best suited for inactive sites or sites where retail operations can be temporarily suspended during excavation activities. For excavation to be most effective, all or the majority of the contaminant plume must be accessible.

Remediation Systems

System Design

Creek Run has designed and installed numerous remediation systems to address soil and groundwater impacted by petroleum hydrocarbons, volatile organic compounds (VOCs), semi-volatile organic compounds (SVOCs), light non-aqueous phase liquids (LNAPLs – free product), and heavy metals. Based on a thorough understanding of soil properties, contaminant distribution, and hydrogeologic conditions gained during subsurface investigation activities, Creek Run evaluates a variety of remedial approaches to identify the most appropriate remedial method(s) for addressing site-specific conditions and achieving regulatory closure at minimum cost.

If active remediation is warranted, Creek Run will conduct pilot tests to identify the most effective remedial method and acquire information needed to design a full scale remediation system. Pilot testing typically involves installation of test wells, followed by field tests ranging in duration from a few hours to several days. Data gathered during pilot testing is evaluated to assess contaminant removal efficiency and equipment requirements for a full scale system. Creek Run has extensive experience in pilot testing, test interpretation, and full scale system design for the following remedial methods: air sparging, soil vapor extraction, dual and multiple phase extraction, bioventing and biosparging.

Creek Run routinely performs aquifer pumping tests, slug tests, and soil permeability analyses to quantify basic soil and bedrock properties that control groundwater flow and contaminant migration. During remedial feasibility testing, Creek Run has utilized GFLOW groundwater flow modeling software to simulate the effects of groundwater extraction and infiltration of treated water. Commercially available fate and transport modeling software has been utilized to quantify exposure risks by predicting the rate of contaminant migration and degradation at several petroleum-impacted sites.

System Construction Management

Based on a conceptual remedial plan, Creek Run can prepare detailed engineering drawings and bid specifications for all phases of soil and groundwater remediation projects. Clear, concise Request for Quote (RFQ) documents are prepared and submitted to multiple, pre-qualified bidders and the quotes are carefully reviewed to ensure cost effectiveness. Creek Run works closely with selected subcontractors throughout the construction activities. If requested, Creek Run can prepare applications and acquire air discharge, treated water discharge, and building permits as required.

A Health and Safety Plan (HASP) is prepared before commencement of field operations and strictly adhered to throughout the project. On-site construction operations are conducted by OSHA 40-hour HAZWOPER-trained subcontractors under the direct supervision of experienced Creek Run personnel. The Creek Run supervisor can provide verbal or written progress reports as requested by the client (i.e. daily, weekly, or on call). Remedial construction activities will be fully documented in a Corrective Action Implementation Report (CAIR) submitted within 60 days of completion of the project. The CAIR will include As-Built drawings, photographs, equipment specifications, and copies of permits and clearances.

System Evaluation

Operation & Maintenance

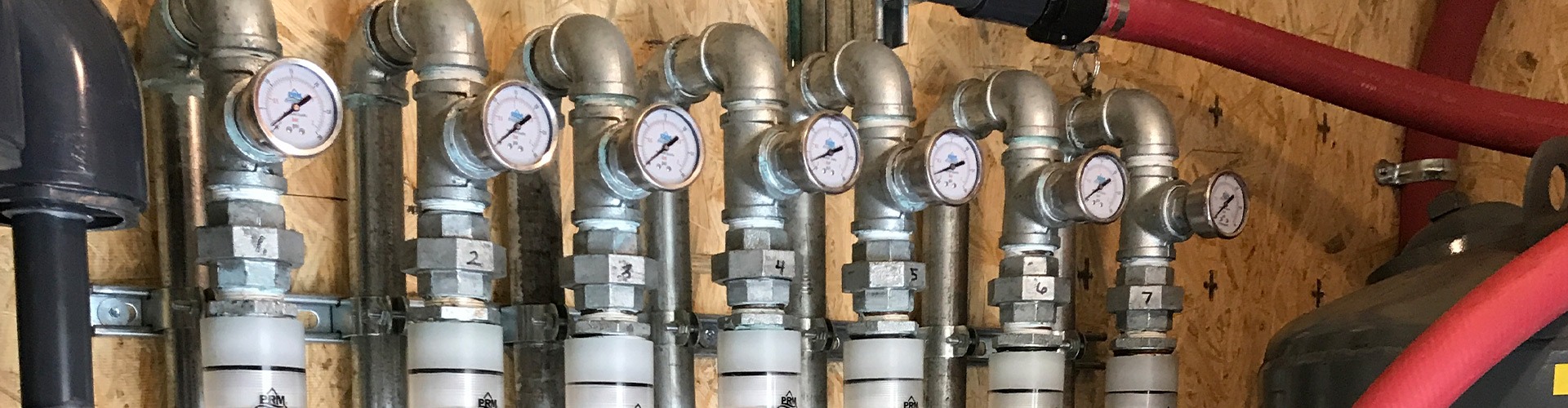

Creek Run successfully operates a variety of soil and groundwater remediation systems throughout Indiana. Treatment technologies include soil vapor extraction (SVE), air sparge (AS), dual phase extraction (DPE), multiple phase extraction (MPE), pump and treat, biovent, passive/active free product recovery units, and treated water infiltration networks. Major components within these systems include liquid ring vacuum pumps, regenerative blowers, air strippers, granulated activated carbon vessels, oil/water separators, transfer pumps, rotary vane sparge compressors, air compressors, pneumatic groundwater pumps, and assorted manifolds, flow meters, and sensors. All Creek Run remediation systems are equipped with a programmable logic controller (PLC) to allow remote monitoring of operations.

Creek Run engineers and technicians are skilled in troubleshooting equipment malfunctions, determining if remedial components can be repaired or need to be replaced, and performing the necessary repairs or replacements to restore systems to full operation. Once a system is operational, Creek Run professionals fine-tune surface and subsurface remedial components to maximize system performance (i.e. increase run time and the rate of contaminant removal).

In addition to troubleshooting equipment problems and restoring remediation systems to operational status, Creek Run can provide regularly scheduled operation and maintenance (O&M) services to keep systems operating efficiently. Our extensive, ongoing operations require Creek Run to maintain close working relationships with system builders, equipment manufacturers, and other remedial service providers. These long-term relationships allow Creek Run to access specialized remedial experts and obtain preferential pricing for components and supplies – factors that can benefit your remedial efforts.